Pulsarlube

Pulsarlube

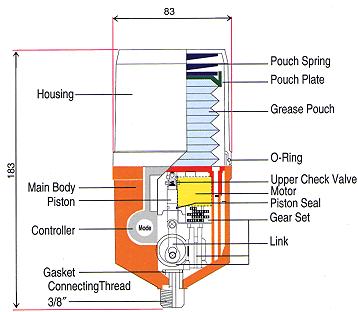

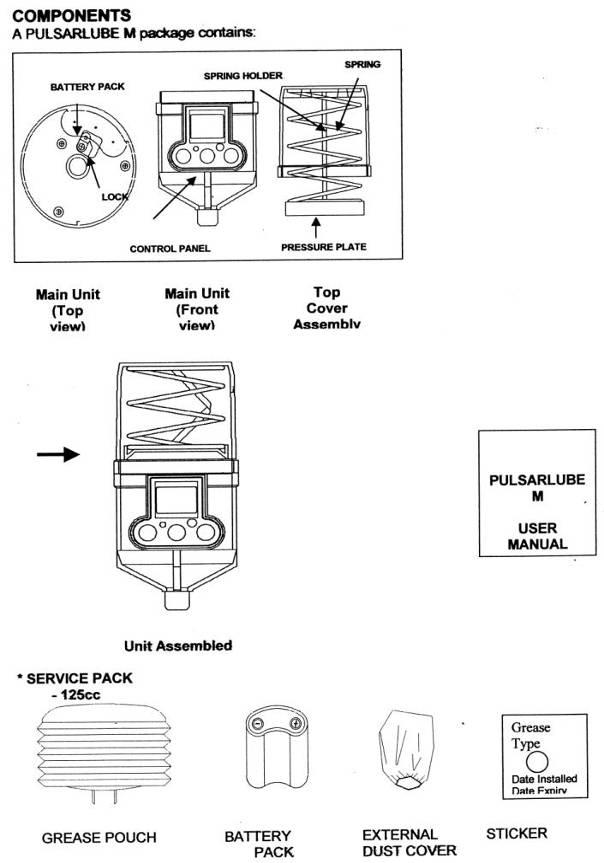

Operating PrinciplesPULSARLUBE M, a single-point automatic grease dispenser is designed to ensure reliable lubrication and cut lubrication costs with an advanced electric control mechanism. It consists of a vertical feed pump, motor/gear set, and microprocessor control system, allowing operating pressure up to 20kg-f/cm2 (280psi). The lubricant is supplied in 125cc or 250cc PULSARLUBE M pouch. Grease pouch and battery pack are replaceable in one package. PULSARLUBE M is designed to operate across a wide temperature range from -15 to +60°C A carefully selected full range of high performance lubricants enables accurate selection of grease : i.e. mineral based multipurpose, heavy duty, high speed, fully synthetic food grade(USDA H1), high temperature and cold temperature lubricants. PULSARLUBE M optional dispensing rates from 1 to 12 months in a single unit. |

|

|

Adjustment GuidelinesIn the chart below are some guidelines for bearing lubrication requirements. Requirements may vary with individual bearing types or operating conditions. Always refer to the bearing manufacturers maintenance guide if uncertain of the required greasing rate |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Grease Selection Guidelines |

||

|

Model |

Grease Type |

Description |

|

PL1 |

Multi Purpose |

High

performance NLGI 2EP grease for multipurpose application to moderately high

temperature or loaded applications. (Green) |

|

PL2 |

Heavy Duty |

High

performance NLGI 2EP grease for heavy-duty applications. Dark gray

colored (contains MoS2). |

|

PL3 |

High Speed |

High

performance NLGI 1 grease specially designed for high-speed applications

(above 3,000 rpm). |

|

PL4 |

Food Grade |

USDA H1

rated NLGI 1 High performance Aluminum Complex grease for food applications. |

|

PL5 |

High Temperature |

Fully

synthetic high performance NLGI 2 grease for extreme temperature

applications. |

|

PL6 |

Multi Purpose |

Yellowish

colored PL1 for applications where use of dark color grease is not desirable. |

|

PL7 |

Cold Temperature |

High

performance EP grease specially designed for cold temperature

applications (below 0ºC/32ºF). |

|

OEM filling is available on demand. For

specific terms and conditions, please contact your local distributor or the

manufacturer |

||

|

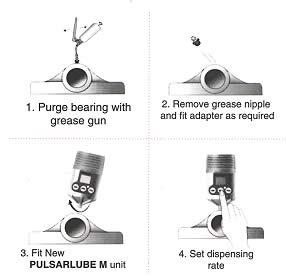

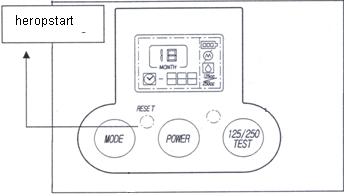

OperationInsert the PULSARLUBE M BATTERY PACK into the battery compartment of main unit. Unscrew the cap of PULSARLUBE M GREASE POUCH. Position the pouch outlet onto the pump suction inlet. Fit the Top cover to main unit. Be careful! It is high-tension spring-loaded and needs caution. Turn a new PULSARLUBE M on by depressing the POWER button for two seconds. And then confirm LCD turned on and red LED blinks. As long as LCD is displayed, the unit is working. To test unit operation, simply follow the FUNCTION TEST MODE:

For any malfunction or trouble encountered, please refer to troubleshooting guideline. Depress MODE button to set dispensing rate. Each time MODE button is depressed; the dispensing rate changes from 1,2,3,6, and 12 month. |

|

|

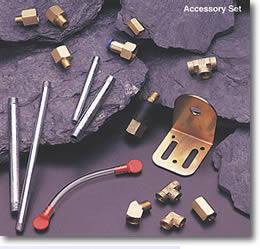

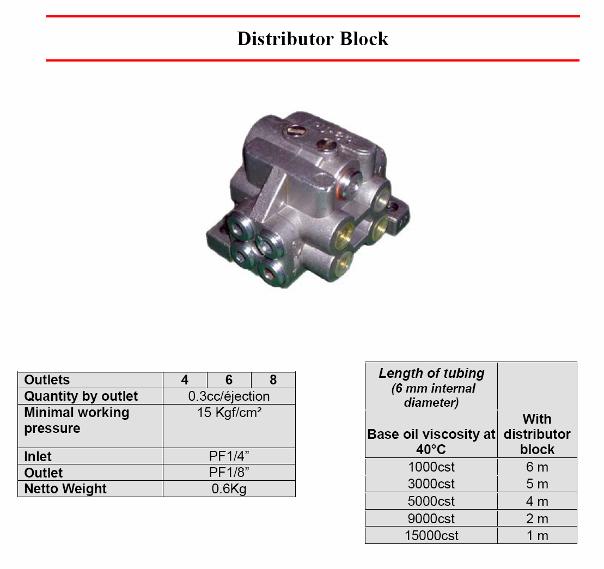

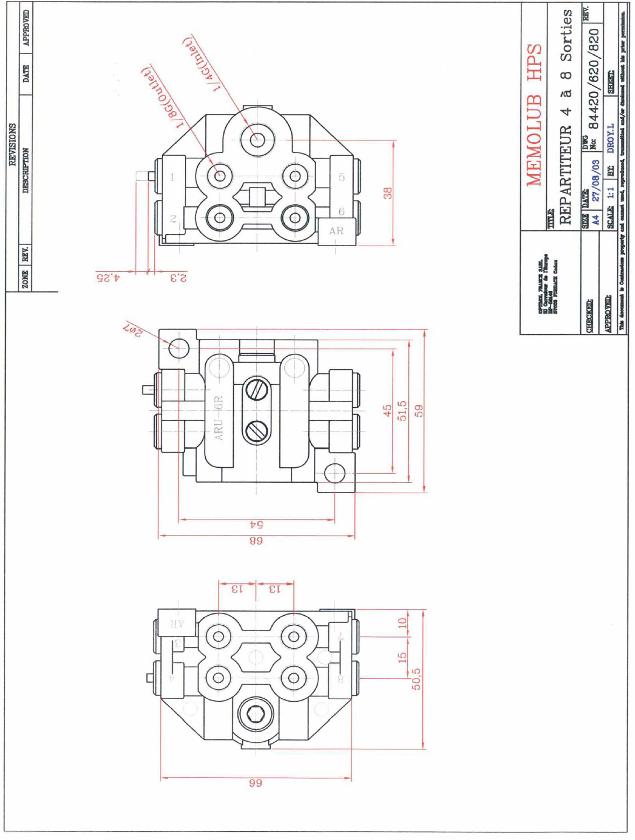

Remark

- If one outlet is clogged, all other ones will be clogged.

- It is necessary to use a bridging element to adapt a distributor block to 3, 5 or 7 outlets.

Service pack is also available at 250CC

|

Rood licht: waarschuwing Begint te knipperen wanneer er zich een van de volgende situtaties zich voordoet:

|